AC DRIVES

AC Drive - AC Drives, DC Drives, Servo Drives, SINAMICS G110 Inverter Chassis Units, Inverter Chassis Units,Frequency Inverters, Control Panels Instruments, Custom Control Panels, PLC Turnkey Projects

Micromaster 420/430/440, Inverters, 0.12 kW to 250 kW

Sharpen your competitive edge. Totally Integrated Automation

With Totally integrated Automation (TIA), Siemens is the only manufacturer to offer an integrated range of products and systems or automation in all sectors - from incoming goods to out going goods. from the field level through the production control level to connection with the corporate management level. On the basis of TIA, we implement solutions that are perfectly tailored to your specific requirements and are characterized by a unique level of integration. This integration not only ensure significant reduction in interface costs but also guarantees the highest level of transparency across all levels.

It goes without saying that you profit from Totally integrated Automation during the entire life cycle of your plant - form the first planning steps, through operation, right up to modernization. Consistent integration in the further development of our products and systems guarantees a high degree of investment security here.

Totally integrated Automation makes a crucial contribution towards optimizing everything that happens in the plant and thus creates the conditions for a significant increase in productivity.

Micromaster

Inverter

Inverters

-

Micromaster 420/430/440

|

||||||||||||||||||||

Micromaster 430

- Easy, guided start-up

- Modular construction allows maximum configuration flexibility

- Three fully programmable isolated digital inputs

- One analog input (0 V to 10 V, scaleable) or for use as 4th digital input

- One programmable analog output (0 mA to 20 mA)

- One programmable relay output (30 V DC/5 A resis tive load; 250 V AC/2A in ductive load)

- Low-noise motor operation through high pulse frequency, adjustable (observe derating if necessary)

- Complete protection for motor and inverter.

Application :

The MICRO MASTER 420 in verter is suitable for a variety of variable-speed drive applications. It is especially suitable for applications with pumps, fans and in conveyor systems. It is the ideal cost-optimized frequency inverter solution. The inverter is especially characterized by its customer-oriented performance and easeof-use. Its large mains voltage range enables it to be used all over the world.

Design:

The MICRO MASTER 420 in verter has a modular design. The operator panels and communication modules can be easily exchanged without requiring any tools.

Main characteristics :

Micromaster 420

-

Options (overview) :

- EMC filter, Class A/B

- LC filter

- Line commutating chokes

- Output chokes

- Gland plates

- Basic Operator Panel (BOP) for parameterizing the inverter

- Advanced Operator Panel (AOP) with multi-language plain text display

- Asian Advanced Operator Panel (AAOP) with Chinese and English plain text display

- Cyrillic Advanced Operator Panel (CAOP) with Cyrillic, German and English plain text display

- Communication modules - PROFIBUS

- PC connection kits Mounting kits for installing the operator panels in the control cabinet doors

- PC start-up programs executable under Windows 98 and NT/2000/ME/XP Professional

- TIA integration with Drive ES

- The MICROMASTER 420 inverter complies with requirements of the EU voltage guideline

- The MICROMASTER 420 inverter has the CE marking

- acc. to and c certified

- C-tick

- DeviceNet

- CANopen

International standards :

Note : See Appendix for standards

- Easy, guided startup

- Modular construction allows maximum configuration flexibility

- Six programmable isolated digital inputs

- Two scaleable analog inputs (0 V to 10 V, 0 mA to 20 mA) can also be used as a 7th/8th digital input

- Two programmable analog outputs (0 mA to 20 mA)

- Three programmable relay outputs (30 V DC/5 A resis tive load; 250 V AC/2A inductive load)

- Low-noise motor operation thanks to high pulse frequencies, adjustable (observe derating if necessary)

- Complete protection for motor and inverter

- Control of up to three additional drives on the basis of PID control (motor staging)

- Operation of drive directly on mains (with external by pass circuit)

- Low-energy mode

- Detects dry run of pumps (belt failure detection)

Application :

The MICROMASTER 430 in verter is suitable for a variety of variablespeed drive applications. Its flexibility provides for a wide Spectrum of applications. It is especially suitable for use with industrial pumps and fans. The inverter is especially characterized by its Customer oriented performance and ease of use. It has more inputs and outputs than the MICRO MASTER 420, an optimized operator panel with manual/automatic switchover and adapted software functionality.

Design:

The MICROMASTER 430 in verter has a modular design. The operator panels and communication modules can beeasily exchanged.

Main characteristics :

-

Options (overview) :

- Line commutating chokes

- Output chokes

- LC filter and sinusoidal filter

- Gland plates

- Basic Operator Panel 2 (BOP-2) for parameterizing the inverter

- Communication modules - PROF/BUS

- PC connection kits

- Mounting kits for installing the operator panels in the control cabinet doors

- PC start-up tools executable under Windows 98 and NT/2000/ME/ XP Professional.

- TlA integration with Drive ES

- The MICROMAS 430 inverter Complies with the requirements of the EU low voltage guideline

- The MICROMASTER 430 inverter has the CE marking

- acc. to and c certified

- C-tick

- DeviceNet

- CANopen

International standards :

Note : See Appendix for standards

Micromaster 430

Micromaster 430

Micromaster 430

- Easy, guided start-up

- Modular construction allows maximum configuration flexibility

- Six programmable isolated digital inputs

- Two scaleable analog inputs (0 V to 10 V, 0 mA to 20 mA) can also be used as a 7th/8th digital input

- Two programmable analog outputs (0 mA to 20 mA)

- Three programmable relay outputs (30 V DC/5 A resistive load; 250 V AC/2A inductive load)

- Low-noise motor operation thanks to high pulse frequencies, adjustable (observe derating if necessary)

- Complete protection for motor and inverter.

Application :

The MICROMASTER 440 inverter is suitable for a variety of variable speed drive applications. Its flexibility provides for a wide spectrum of applications. These also include cranes and hoisting gear, high-bay warehouses, production machines for food, beverages and tobacco, packaging machines etc.; i.e. applications which require the frequency inverter to have a higher functionality and dynamic response than usual. The inverter is especially characterized by its customer-oriented performance and ease of use. Its large mains voltage range enables it to be used all over the world.

Design:

The MICRO MASTER 440 inverter has a modular design. The operator panels and modules can be easily exchanged.

Main characteristics :

-

Options (overview) :

- EMC filter, Class A/B

- LC filter and sinusoidal filter Line commutating chokes Output chokes

- Gland Plates

- Basic Operator Panel (BOP) for parameterizing the inverter

- Plain text Advanced Operator Panel (AOP) with multilanguage display

- Plain text Asian Advanced Operator Panel (AAOP) with Chinese and English display

- Plain text Cyrillic Advanced Operator Panel (CAOP) with Cyrillic, German and English display Communication modules - PROFIBUS

- Pulse encoder evaluation module

- PC connection kits

- Mounting kits for installing the operator panels in the control cabinet doors

- PC start-up tools executable under Windows 98 and NT/2000/ME/XP Professional

- TIA integration with Drive ES.

- The MICROMASTER 440 inverter complies with the requirements of the EU low voltage guideline

- The MICROMASTER 440 inverter has the CE marking

- acc. to and c certified

- C-tick

- DeviceNet

- CANopen

International standards :

Note : See Appendix for standards

Micromaster 440

Micromaster 440

Micromaster 440

-

Micromaster 420/430/440 - Appendix

Overview of frequency inverters/converters for SIMATIC ET 200 distributed I/O (continued) Frequency inverters are available for the SIMATIC ET 200 distributed I/O that are fully system integrated modules. Inverters are available for the finely modular SIMATIC ET 200S FC system to the IP20 degree of protection as well as for the cabinet free SIMATIC ET 200pro FC system to the IP65 degree protection. With a broad range of possibilities, the frequency inverters expand the functional scope of the modular modules that are available in both systems e.g. inputs and outputs, technology modules, direct and soft starters). With suitable interface modules, connection to PROFIBUS and PROFINET IS possible via the ET 200 system bus as well as integration of PLC functionality into the system. Failsafe frequency inverter functions can be activated locally or via PROFlsafe. An overview of the features of the SIMATIC ET 200 pro Frequency Inver er series IS given In the table below. The complete product spectrum including ordering data, technical data and explanations can be found in Catalog IK PI "Industrial Communication for Automation and Drives" (SIMATIC ET 200 pro FC will be available soon)

|

||||||||||||||||||||||||||||||

Standard frequency inverters

Failsafe Frequency inverters

-

Overview of SINAMICS G110 inverter chassis units

SINAMICS G110 inverter chassis unit is a versatile drive. The table provides an overview of the features of this product. The complete range of products together with ordering data, technical data and explanations are indicated in the D 11.1 Catalog "SINAMICS G110/SINAMICS G120 Inverter Chassis Units and SINAMICS G120 D Distributed Frequency Inverters"

|

||||||||||||||||||||||||||||||||

Inverter Chassis Units

-

Overview of SINAMICS G120 inverter chassis units

The SINAMICS G120 inverter chassis unit is a modular drive. The table provides an overview of the features of this products. The Complete ragne of products together with ordering data, technical data and explanations are indicated in the D 11.1 Catalog "SINAMICS G110/SINAMICS G120 Inverter Chassis Units and SINAMICS G120 Distributed Frequency Inverters"

|

||||||||||||||||||||||||||||||||

Inverter Chassis Units

-

Overview of SINAMICS G120D distributed frequency inverters

The SINAMICS G120D frequency inverter is a modular drive. The table provides an overview of the features of this products. The Complete ragne of products together with ordering data, technical data and explanations are indicated in the D 11.1 Catalog "SINAMICS G110/SINAMICS G120 Inverter Chassis Units and SINAMICS G120D Distributed Frequency Inverters"

|

||||||||||||||||||||||||||||||||

Distributed-Frequency Inverters

A detailed knowledge of the range of products and services available is essential when pianning and configuring automation systems. It goes without saying that this information must always be fully up- to-date.

The Siemens Automation and Drives Group (A&D) has therefore built up a comprehensive range of information in the World Wide Web, which offers quick and easy access to all data required.

You will find everything you need to know about products, systems and services.

Automation

A detailed knowledge of the range of products and services available is essential when pianning and configuring automation systems. It goes without saying that this information must always be fully up- to-date.

Detailed information together with convenient interactive functions:

The Offline Mall CA 01 covers more than 80,000 products and thus provides a full summary of the Siemens Automation and Drives product base.

Here you will find everything that you need to solve tasks in the fields of automation, switchgear, installation and drives. All information is linked into a user interface which is easy to work with and intuitive.

After selecting the product of your choice you can order at the press of a button, by fax or by online link.

The Siemens Automation and Drives Group (A&D) has therefore built up a comprehensive range of information in the World Wide Web, which offers quick and easy access to all data required.

You will find everything you need to know about products, systems and services.

Drives

The A&D Mall is the virtual department store of Siemens AG in the Internet. Here you have access to a huge range of products presented in electronic catalogs in an informative and attractive way.

Data transfer via EDIFACT allows the whole procedure from selection through ordering to tracking of the order to be carried out online via the Internet.

Numerous functions are available to support you.

For example, powerful search functions make it easy to find the required products, which can be immediately checked for availability. Customer-specific discounts and preparation of quotes can be carried out online as well as order tracking and tracing.

A&D Mall

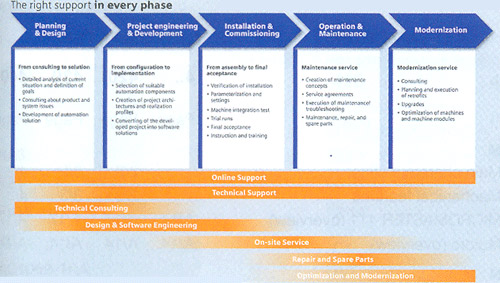

In the face of harsh competition you need optimum conditions to op ahead all the time:

strong starting position, a sophisticated strategy and team for necessary support - in every phase. Service & Support from Siemens provides this support with a complete range of different services for automation and drives.

In every phase: from planning and commissioning to maintenance and upgrading.

Our specialists know when and where to act to keep the producy and cost-effectiveness of your system running in top form.

A&D Mall

Technical consulting :

Support in the planning and designing of your project from detailed actual-state analysis, target definition and consulting on product and system questions right to the creation of the automation solution.

Configuration and software engineering :Support in configuring and developing with customer-oriented services from actual configuration to implementation of theautomation project.

Service on site : With service on site we offer services for startup and maintenance, essential for ensuring system availability.In Germany : Phone: +49 (0)180 50 50 444 (0.14 €/min. from the German fixed network)

In the United States, call toll-free: Phone: +1 800 333 7421

In Canada, call:

Phone: +1 888 303 3353

Service on Site

Online Support

Phone: +49 (0)180 50 50 222,

Fax: +49 (0)180 50 50 223

(0.14 €/min. from the German fixed network)

E-Mail: adsupport@siemens.com

In the United States, call toll-free:

Phone: +1 800 333 7421, Fax: +1 423 262 2200

E-Mail: solutions.support@sea.siemens.com

In Canada, call:

Phone: +1 888 303 3353

E-Mail: cic@siemens.ca

In Asia:

Phone: +86 10 6475 7575, Fax: +86 10 6474 7474

E-Mail: adsupport.asia@siemens.com