System Solutions with Emphasis

System Solutions With Emphasis, System Solutions, Module Spectrums, I/O Modules, PC Based Process Controls, Visualization Systems, Machine Visualization Systems, Industrial Networking Systems

System Solutions with Emphasis For System Solutions with Emphasis on Production Engineering Simatic S7-300

Machine and plant constructors are being increasingly requested to offer more flexible and productive machines at reduced prices. This places new demands on the automation systems with respect to e.g. scope of functions, processing speed and size, as well as engineering and networking. PLCs are required with a large scope of functions and high processing speeds in a compact design. The networking facilities should be improved at the same time, but the engineering requirements should be simultaneously reduced.

SIMATIC® S7-300® is the most widely sold PLC within the context of Totally Integrated Automation with many successful reference applications worldwide found in many different industrial sectors. S7-300 users profit from the experience and global servicing facilities of the market leader as well as the quality associated with SIMATIC. This is the basis for increasing profits and improving competitiveness using innovative automation solutions.

The S7-300 has been designed for system solutions with the emphasis on production engineering, and is a universal automation platform providing optimum solutions for applications with central or distributed designs. Permanent innovations upgrade this automation platform even further. Examples include regular further development of the powerful CPU modules whose range now also includes a CPU with integral Ethernet / PROFlnet interface for Component based Automation.

-

The SIMATIC S7-300 offers solutions for the most diverse automation tasks in the following areas :

- Production engineering

- Automobile industry

- General machine construction

- Specialized machine construction

- Machine construction in series, OEM

- Processing of plastics

- Packaging industry

- Food and drink industry

- Process engineering

- Special Application

- Low Engineering costs

- Low Operating costs

System Solutions with Emphasis

System Solutions with Emphasis

CPU Spectrum

-

Design and Networking

- Multi-point interface - MPI

- Profibus DP

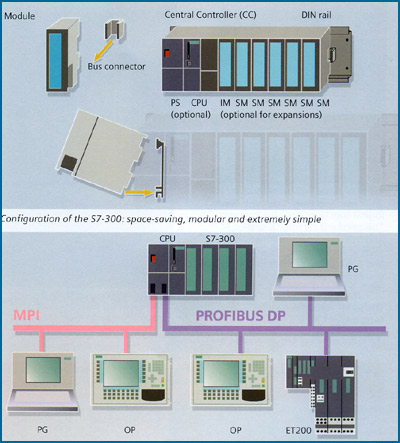

Desing : The S7-300 enables a space-saving modular configuration to machine controllers adapted to the task at hand, without taking slot rules into consideration. A fan is not necessary during operation. Apart from the modules, only a DIN rail is required where the modules are swung into place and secured by screws. A configuration is then possible which is robust and electro-magnetically compatible

The backplane bus is integrated into the module and is assembled by insertion in the bus connector. The diverse S7-300 module spectrum can be used for centralized expansions as well as for simple configuration of distributed structures with ET 200M; this results in a very cost-efficient spare-parts maintenance.

Powerful, flexible networking Interfaces that are directly integrated in the CPUs permit the configuration of a powerful communication landscape that employs standard bus technologies, e.g. for HMI and programming device func tions. Sufficient connectivity is provided for numerous HMI devices. A routing function enables a programming device to be connected at any point in the network and to address all network nodes.

Design and Networking

-

CPU Spectrum :

For setting up a programmable controller system, the user can choose from a graded spectrum of CPUs, from the starter model to the high-performance CPU. The CPUs enable short machine cycles thanks to their high processing speed. The narrow module width permits compact controller configurations and small control cabinet dimensions.

The so-called standard CPUs have a width of only 40 mm and are also available in two fail-safe designs.

A variety of compact CPUs with a width of 80 or 120 mm featuring additional integrated I/Os and technological functions are also available. This onboard I/O (digital/analog) and the technological functions, such as for counting, positioning and closed-loop control may save you from investing in additional modules.

The range is rounded off by a special technology CPU with powerful process functions.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

DP Interfaces

Motion Control Functuions

Fail-safe systems are used where the highest safety standards for personnel. machines and the environment must be guaranteed, i.e. accidents and damage as the result of an error must be avoided at all costs.

An additional SIMATIC fail-safe controller is now available with the S7-300F especially for safety oriented and simultaneously distributed applications in the production industry.

The predominant feature of the S7-300F is the combination of stan dard plant automation and safety engineering in a single system. This means that not only "normal" communication but also safety-oriented communication (using the PROFlsafe-Profile) with PROFIBU5 DP between central controller and I/O takes place - intrinsic "normal" communication is not required. This fusion of standard and safety automation considerably reduces the expenditure for configuring and designing modern safety-oriented plants.

The S7-300F achieves the safety-oriented functions through an F-CPU as well as a fail-safe modules, which can be used in the S7-300 as well as in the ET 200M and ET 200S distributed I/O systems. A special library is available from the German Technical Inspectorate (TUV) providing certified programming examples. The programming takes place with the standard LAD and FBD programming languages.

Fail-safe motor starters connected to ET 200S are available as an ideal supplement to the S7-300F.

Motor Starters

- All CPUs can be programmed in STL, LAD and FBD basic languages.

- Should the S7-SCL high-level language be used, CPUs 313C, 314 and above are recommended.

- If graphic concept languages (S7-GRAPH, S7-HiGraph and (FC) are used, CPUs 314 and higher are recommended.

The S7-300 is programmed with the basic software STEP 7 or STEP 7 Lite. This enables the performance capa-

bility of the S7-300 to be used in a simple, user-friendly manner. Both contain functions for all phases of an automation project - from configuring to commissioning, testing and servicing.

STEP 7 Lite: The cost-efficient software STEP 7 Lite is available to achieve stand-alone applications with the SIMATIC S7-300.

STEP 7 Lite is characterized by very fast entry into programming and simple project handling.

Additional SIMATIC software packages, such as Engineering Tools, cannot be used for simulation. Programs which were generated with 5TEP 7-Lite, can also be processed using STEP 7.

STEP 7 : STEP 7 is used for, among other things, larger or more complex applications, with which, e.g. programming with high-level languages or graphic concept languages (see Engineering Tools) takes place or the use of function or communications modules is required.

STEP 7 enables the use of additional SIMATIC software packages, for instance Engineering Tools.

Engineering Tools : Engineering Tools open additional possibilities to program automation solutions in a user-friendly, task oriented manner. The following tools are available for programming

S7-SCL : (Structured Control Language), the high-level language based on PASCAL for programming SIMATIC S7/C7 controllers

S7-GRAPH :for graphic configuration of sequential controls for SIMATIC S7/C7

S7-HiGraph® : for graphic description of sequential or asynchronous processes with state graphs for SIMATIC S7/C7

CFC :(Continuous Function Chart), the technological plan for graphic interconnection of complex functions for SIMATIC S7

Distributed Safety: Software package for generating safety- related programs in LAD and FBD, including F library with programming examples

The use of Engineering Tools is advantageous above all for larger, more complex applications and correspondingly greater CPUs.

CPUs/Engineering Tools:

- Creating your own Web pages with random HTML tools whereby the process variables of the S7-300 are simply assigned to the HTML objects.

- Monitoring the S7-300 using these Web pages with a standard browser.

- Sending e-mails from the user profile of the S7-300 through FC calls.

- Remote programming through the TCPIIP using telephone network as well (e.g. ISDN).

Totally Integrated Automation With a single, completely integrated and uniform system you can solve all your automation tasks! Every function is available from one vendor.

Distributed preprocessing (distributed intelligence) makes new concepts in the plant and machine construction possible with every advantage such as re-usability of the software, faster commissioning times and greater availability.

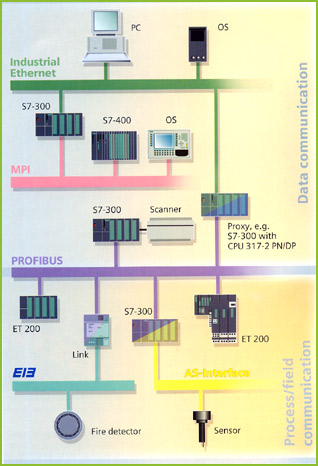

Of great significance in the system are communication networks:

Industrial Ethernet (IEEE 802.3 and 802.3u) - the international standard for area and cell networking.

PROFIBUS (lEC 61158/EN 50170) the international standard for the cell and field areas, as well as PROFIBUS PA for intrinsically-safe process automation applications. PROFlnet, the Ethernet standard of PROFIBUS International (PNO), allows connection of PROFIBUS segments to Industrial Ethernet using a PROFlnet device with proxy function.

AS-Interface (EN 50295)

the international standard for communication with sensors and actuators.

EIB (EN 50090, ANSI EtA 776) the world-wide standardized build

ing installation system and basis for building automation.

MPI - Multi point interface

for communication between CPUs, PG/PC and TO/OP.

Point-to-point coupling

for communication between two nodes with special protocols. The point-to-point structure represents the simplest communication form. Different special protocols are used (e.g. RK 512, 3964(R) and ASCII).

Integration in the IT world

The S7-300 enables the modern IT world to be integrated into automation technology.

The following functions are possible using the insertable CP

(CP 343-1 IT):

Communication - Ethernet, PROFIBUS

- Digital and analog I/O modules for almost all types of signals, including interrupt processing and diagnostics

- Digital and analog Ex I/O modules for use in hazardous areas

- Function modules for counting / measuring, all sorts of positioning functions, cam control and loop control

- Communication modules for point-to-point coupling or bus communication using AS-Inter face, PROFIBUS and Industrial Ethernet with IT functionality

- Load supply units which provide 24 V DC operating voltage Interface modules for connecting racks for multi-tier installation of the SIMATIC S7-300 Expansion options

The comprehensive range of modules enables modular adaptation of the S7-300 to a wide variety of applications.

The following are available:

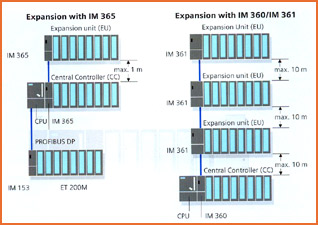

Should the automation task require more than 8 modules, the central controller (CC) of the S7-300 can be expanded using expansion units (EU)'. Altogether up to 32 modules can be used, up to 8 per expansion unit.

Communication between the individual devices is carried out independently by interface modules (IM).

In the case of plants covering an extensive area, CC/EUs can be configured in greater distances (up to 10 m).

This means that for a single-tier installation, the maximum configuration is 256I/O, with up to 1024I/O for multiple line installations.

For a distributed system using PROFIBUS DP 65536 I/O connections can be used (up to 125 stations, for example ET 200M using IM 153).

The slots are freely addressable, i.e. no slot rules exist2.

Module spectrum

Point-to-point coupling with data transmission rates up to 115 kbit/s and various protocols, e.g. for connecting printers, scanners and third-party devices Connection to the field bus AS-Inter face for communicating with binary sensors and actuators Connection to PROFIBUS using either the DP or the FMS protocol or by using fiber-optic cable. Connection of PROFIBUS PA field devices using DP/PA link Connection to Industrial Ethernet using ISO/TCP or TCP/IP protocol for data communication

- Controlled positioning in rap id-traverse/creep-speed mode

- Point-to-point positioning and profiles using stepper and servomotors

- Point-to-point multi-axis interpolation using stepper and servomotors Connection of positioning drives with PROFIBUS DP PID controller with backup capability and integrated, online self configuration for different types of controllers (continuous controllers, stepper controllers, pulse controllers)

Counting in different operating modes up to 500 kHz, measuring up to 100 kHz and proportioning Cam controls with up to 13 cam tracks per module

All sorts of positioning tasks:

Signal modules are the interface of the SIMATIC 57-300 to the process. A number of various digital and analog modules make those I/Os available which are required for the respective task.

Easy installation :

Sensors and actuators are connected using front connectors. The connector is simply plugged into the new module when the module is replaced, the wiring remains unchanged. Coding of the front connector prevents confusion.

Fast connection :

Using SIMATIC TOP connect makes it even easier to connect (not for onboard I/Os of compact CPUs). You can choose between prewired front connectors with individual strands and a completely modular building block system, consisting of front connector module, cable and terminal block.

High packaging density :

The large number of channels on each module is the one reason for the space saving design of the 57-300: Modules are available with 8 to 32 channels (digital) and 2 to 8 channels (analog).

Easy parameterization :

Modules are configured and param eterized using STEP 7, there are no complicated switch settings. Data is stored centrally and, when modules have been replaced, automatically transferred to the new module to prevent setup errors. No software upgrading is necessary when using new modules. Configurations which have been ca~ried out once can be repeated identically any number of times, e.g. for series machines.

Diagnostics, interrupts :

Many modules monitor signal acquisition (diagnostics) and signals from the process as well (process alarm). In this way it is possible to react quickly to any irregularities or process events. Whether the controller should react and what the reaction should be can be parameterized in STEP 7.

Special modules :

The simulation module can be inserted in the S7-300 for testing and simulation purposes. It enables encoder signals to be simulated with the switch and displays output signals using LEDs. The module can be plugged in anywhere without worrying about slot rules.

The dummy module reserves a slot which has not yet been configured. The mechanical configuration and address allocation remain unchanged when the module is slotted at a later date. On the following pages you will find criteria for selecting the right signal module for a given application.

Detailed technical specifications are available in the latest version of Catalog CA 01