Service, Maintenance, Remote Action

Service - Services, Maintenance - Maintenances, Remote Action, Servo Motors, Micro Automation, Human - Machine Interface HMI - SIMATIC, SIMATIC HMI Human Machine Interface, Harmonic Analysis, Manufacturer, Distributors

For Service, Maintenance, Remote action and more : Communication at every level - S7-200

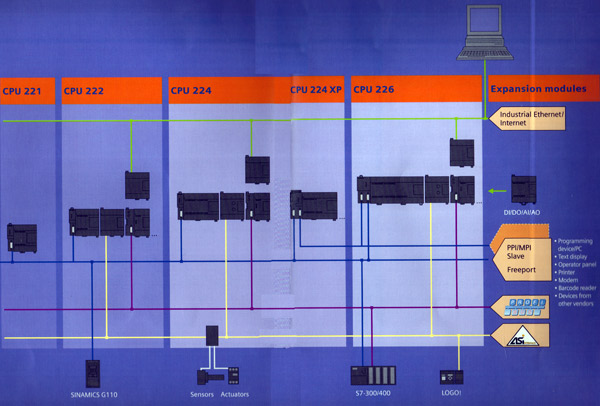

The communication possibilities of the Micro PLC SIMATIC S7-200 are unique. The integrated standard RS 485 interface can operate at date transmission rates from 0.3 to 187.5 kbit/s functioning as follows :

- As a system bus with a maximum of 126 stations. In this capacity, for example, it is possible to network programming devices, SIMATIC HMI products and SIMATIC CPUs without a problem. The integrated PPI protocol is used for pure S7--200 networks. In a network consisting of TIA componets (SIMATIC S7- 300/400 and SIMATIC HM etc.), the s7-200 CPUs are integrated as MPL slaves.

- In programmable mode (up to max. 115.2 kbaud) with user-specific protocols (e.g. ASCII protocol). This means the SIMATIC S7-200 is open for any connected device; for example, it enable connection of a modem, barcode scanner, PC, non-Siemens PLC and much more. By means of the USS protocol for drives, as many 31 SINAMICS frequency converters can be controlled without additional hardware.

- The Modbus RTU Libray included in the package also enables connection to a Modbus RTU network

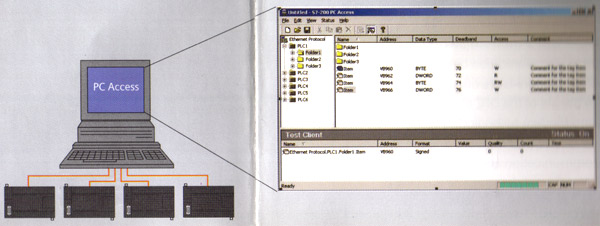

PC Access is the perfect basis for data exchange between S7-200 and PC - rgardless of the communication link selected (PPI, modem, Ethernet / IT CP). As an OPC Server, PC Access offers you the option of writing or reading s7-200 data with Microsoft Excel. As an OPC Client, it can be used for ProTool Pro, WinCC flexible RT, Win CC, etc. With an interface for the visualization via as many as 8 connection, the configuration, programming and monitoring can be implemented from a central location, saving both time and money.

The internet module CP 243-1 IT also offers you fast access by permitting a simple universal connection of the PLC to different computers by means of FTP. The Ethernet module CP 243-1 allows you to access S7-200 process data quickly via Ethernet for archiving or further processing. The configuration support from STEP 7- Micro / WIN ensures simple commissioning and convenient diagnostic options.

-

The S7-200 CPUs can be accessed nearly anywhere in the world by modem via wired network or radio.

- Teleservice :

the modem communication option is useful for avoiding expensive service calls. Two modems are all you need for remote use of the complete range of functions such as program transfer, status or control; the communications tools are integrated as a standard feature. External PCMCIA modems can be used as local modems.

- Telcontrol :

you can call up messages and measured values via modem as well as define new setpoints or commands. In this case, one head-end can control nearly unlimited number or tributary stations. The protocols for data transmission are freely selectable, e.g. for text messages directly to a cell phone, error messages to a fax machine or Modbus RTU.

- Peedy PROFIBUS Connection

All 222 - series CPUs or later can be run via the EM 277 communications module as a norm slave on the PROFIBUS DP with a transmission rate of up to 12 Mbit/s. This open feature of the S7-200 to higher-level PROFIBUS DP control levels ensures you cab integrate individual machines into your production line. With the EM 277 expansion module, you can implement PROFIBUS capability of individual machines equipped with S7-200.

- Powerful AS - Interface Connection

The CP 243-2 turns series - 222 CPUs or later into powerful masters on the AS - Interface. According to the new AS - Interface specification V 2.1, you can connect up to 62 stations, making even analog sensors easy to integrate. In accordance with the new AS - Interface specification, you can also connect up to 248 Dls + 186 DOs in the maximum configuration. The max. number of 62 stations can include up to 31 analog modules. The configuration of the slaves and reading / writing of data is supported by the handy AS-Interface Wizard.

PC Access