DC DRIVE

DC Drive - DC Drives, AC Drives, Servo Drives, Power Capacitors, Automatic Power Factor Correction Systems, Detuned Harmonic Filters, Servo Motors, Micro Automation, Custom Control Panels

DC Drive from Kuksons from 0.25 to 100 HP, OEM Units & Drive Panel System

DC DRIVE : Well proven drives Technology : RUGGED, DYNAMICS, & LOW PRICES

Depends on the application. DC Drives are often the most economical drive solution, They also have many advantages in terms of reliability user friendliness & operational, response. A number of technical & commercial flow are as important, as they have been in the post for development of DC DRIVES in many sectors of industry. Drives have gai ned the trust of OEM & END USERES

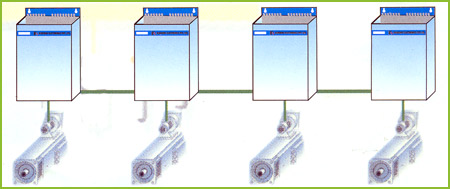

Convential unidirectional drives, reversible by contactors typical application include : Machine Tools, Conveyors, Paper Mills,Sugar Mills, Textile Processors & Sizing Etc.

220VACll PH INPUT : 180VDCFOR ARMATURE

415VACl2PH INPUT : 360VDCFORARMATURE

44OVACl3PH INPUT : 400VDCFORARMATURE

-

KUKSONS offer you a wide range of the Quality Electronic Equipment that have proven themselves under diverse conditions in the Indian industrial environment giving all our customers unmatched value for money.

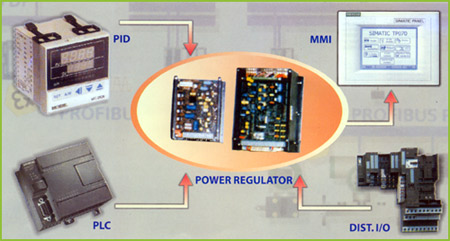

• O.E.M. SYSTEMS • OPEN CHASSIS UNITS • RACK UNITS • PANELS & SYSTEMS KUKSONS Power Regulators or Power Controllers are used for providing controlled AC/DC power from the incoming A.C.mains supply. These compact controllers take Single/Three Phase input employing state of the art technology for providing variable voltage, They assist in the conservation of energy close loop current controller takes care of current limiting.

OVERVIEW & FEATURE : Dedicated industrial compact heater units for almost all applications demanding controlled heating., Low reactive liP Power., Input under voltage protection., No effect of load on mains supply, Can be used with PI D, PLC for integrati ng with automation., Close loop contr:ol., Output current limit., Linear relationship between control voltage & load power.

ADVANTAGE : Power Regulator can be used to provide safe & efficient control of electrical power in a wide variety of application. It rep'laces the present method of heater controls. There is no wear and tear due to absence of many moving parts.

The unit can be driven from two points controllers. This versatility makes it far more superior than contactor control. Especially the facility of using it with continuous controllers result in almost stepless output, not attainable with contactor technique.

It is a modern desig nand offers rjel ia ble operation and accurate control. A single system (Power regulator) that incorporates the high reliability, Compact design, and can be connected via analog interface to higher automation.

APPLICATION : Industrial Furnace, Textile Industry, Industrial Ovens, Drying & Smelting ovens, Extruders, Food Industry, Cable Industry, Rubber Processing machinery & industry. Induction Heating, Electroplating.

Harmonic Analysis

- Power Capacitors

- Automatic Power Factor Correction systems

- Detuned Harmonic Filters

A vast majority of Electrical loads in low industrial installations are inductive in nature. Typical examples are Motors, Transformers, Drives, Flourescent lighting. Such loads consume both Active and Reactive Power. The Active Power is used by the load to meet its real output requirements whereas Reactive Power is used by the load to meet its magnetic field requirements. The Reactive Power ( inductive) is always 90 deg. lagging with respect to the Active Power. it is thus a reality that the flow of Active and Reactive Power always takes place in Electrical installations. his means that the supply system has to be capable of supplying both Active & Reactive Power.

The Supply of Reactive Power from the system results in reduced installation efficiency due to Increased current flow for a given load.Higher voltage drop in the system. Increase in losses of Transformers, Switchgears and Cables. Higher KVA demand from the supply system. Levy of penaltie by the Electrical supply authorities

It is therefore necessary to reduce & manage the flow of Reactive Power to achieve higher efficiency of the Electrical system and reduction in cost of Electricity consumed. The most cost-effective method of reducing and managing Reactive Power is by Power Factor improvement through Power Capacitors.

Due to changing nature of modern electrical installations if has now become necessary to use various types of fixes and variable power capacitors to achieve desired power factor improvement. The methodology followed to achieve a consistently high power factor under modern application conditions is referred to ac "REACTIVE POWER MANAGEMENT" therefore involves proper selectionand use the following products.

Power Capacitors

- Adjustable soft start.

- Adjustable current limit.

- Fuse protection

- Stability Potentiometers.

- RC filter for voltage spike protection

- Adjustable minimum speed settings.

- Meter outputs.

- Tacho/arm feedback field settable

QUALITY AND RELIABILITY WITH TECHNICAL PERFECTION

Single Quadrant Drives : conventional uni-directional drives, reversible by contactors. typical application include machine tools, conveyors packaging & printing machines etc.

RATING VOLTAGE :

415 v. AC 3ph input : 400 v. DC armature

415 v. AC 2ph input : 360 v. DC armature

230 v. AC 1ph input : 180 v. DC armature

STANDARD FEATURES :

Drive Panel Systems

QUALITY AND RELIABILITY :

Drives have gained the trust of O. E. M And End user customer due to their quality and Reliability to ensure this only the best components Are used. Assembly work is carefully monitored And every unit/ panel is 100% tested before dispatch.

PANEL FEATURES :

Meters for armature current, armature Voltage and / or speed, Isolation contractors fuses and switches Control section isolated from power section, Programmable logic controllers. Push buttons and indicating lamps, Reversing contractors (optional), Process instrumentation etc.

O. E. M SUPPORT :

Provides full support to O. E. M. Panel and Machine builders to ensure that you get Exactly what you need. We provide comprehensive application engineering support To Our O. E. M. customers

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| To Order specify : KUK -

A B C A = 01 / 02 / 03 / 05 / 07 / 10 : HP rating B = 1 / 2 / 3 : Input Power Phase C = F (Field), P (PMDC) |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||